Laser processing

Electrically tunable optical solutions for laser processing provide the highest performance in spot size, stability, repeatability and lifetime, while removing bulky and expensive translational optics and f-theta lenses. There are multiple comparative advantages:

Large z-range and large area marking (LAM)

Fast and precise z-axis control

Constant and small spot size

Compact form factor and low weight

Easy integration with analog and digital control options

Coaxial visual inspection

EL-10-42-OF, Optotune’s premium focus tunable lens with integrated optical feedback, is the ideal choice for highly demanding laser processing systems, where fast beam scanning over large 3D volumes is often a necessity. It can be used for all major industrial laser applications at NIR (950-1100nm) and green (532nm) wavelengths:

Marking, engraving, welding, soldering, cutting, ablation, structuring, additive manufacturing.

Our laser processing product portfolio can be quickly added to a production line or installed on a robot arm.

2.5D laser processing

Many laser industries rely on stable laser performance in one plane, with occasional or frequent jumps to a different z-height. Systems with motorized optics are typically employed, being both bulky and slow. Easy addition of the compact EL-10-42 to a standard setup with an f-theta lens provides fast and flexible working distance adjustment over a large z-range, without need for mechanical stages.

As an example, with an f=160 mm f-theta lens, a z-range as large as 100 mm can be achieved, as illustrated below. EL-10-42-OF for 2.5D applications is typically realized in analog signal configuration, where the EL-E-OF-A controller board controls the lens’ optical power by monitoring its optical feedback and temperature, allowing to jump between large z-axis variations within milliseconds.

2.5D laser marking configuration with EL-10-42, galvo scanner and f-theta lens

Marking field and z-ranges with EL-10-42 in three typical f-theta configurations

3D laser processing

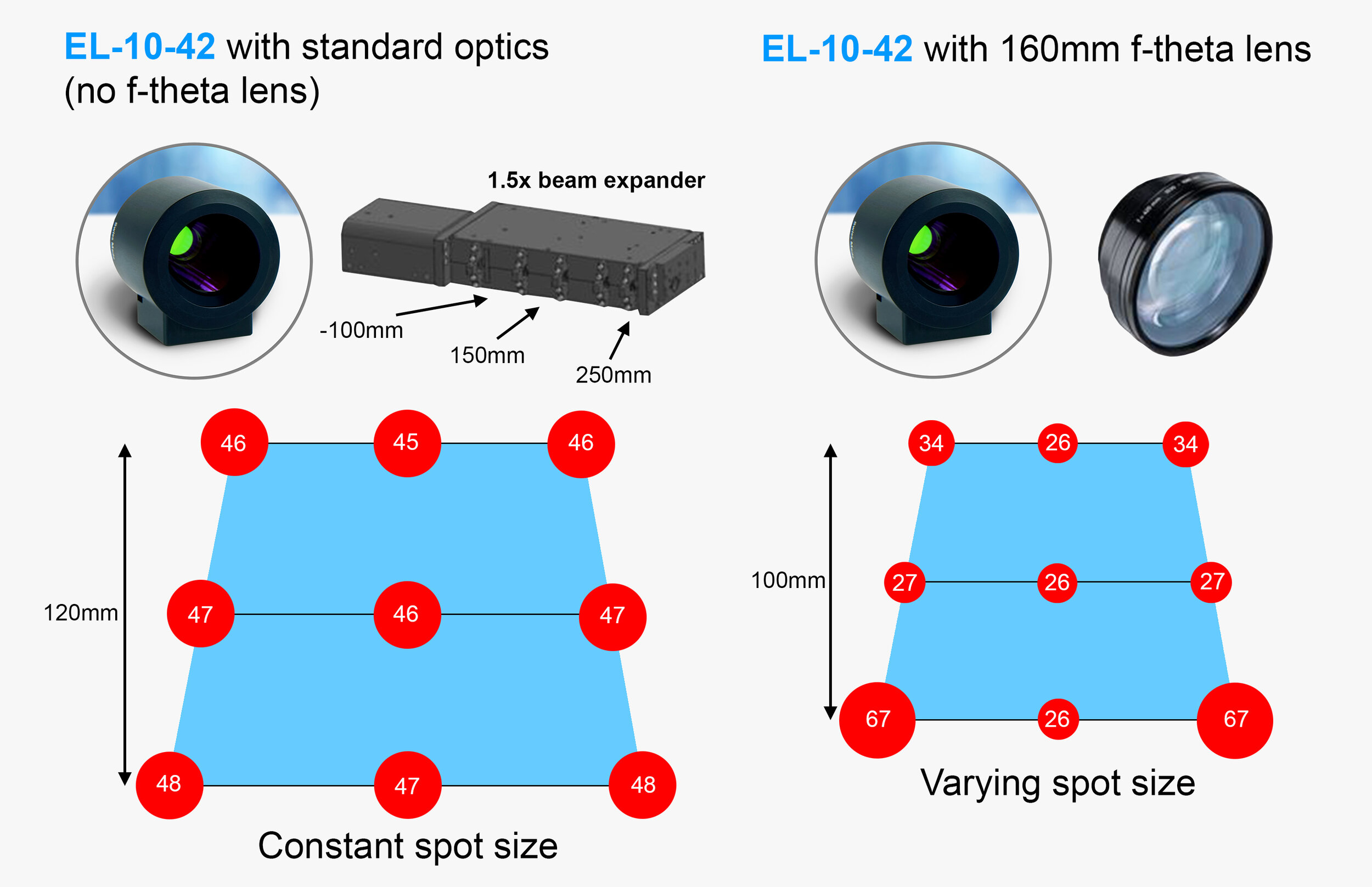

True 3D laser processing is a particular challenge in the industry since either speed, z-range or spot uniformity are compromised. The configuration with the EL-10-42-OF, as shown below, typically supported by the digital controller using the XY2-100 protocol, resolves all these disadvantages and offers simultaneously high speed (up to 6 m/s), large scan field and z-range (up to 1000x1000 mm), and constant spot size in the entire volume. In addition, such a configuration does not require f-theta lenses as the field flattening is performed by the EL-10-42-OF itself; only standard off-the-shelf optics are needed in order to define a starting working distance.

3D laser marking configuration with EL-10-42, galvo scanner and standard optical lens

Comparison of laser spot sizes (in microns) in two configurations: Configuration with EL-10-42-OF and standard optics (no f-theta lens) vs typical f-theta configuration with EL-10-42.

EL-10-42 Focus Tunable Lens for 2.5D & 3D Laser Applications

Fast 3D laser processing with the EL-10-42-OF and the Scaps digital controller

Large Area Marking (1 x 1 m) with a constant spot size using the EL-10-42-OF

Inline inspection

Inline inspection functionality, also based on the liquid lens technology, allows for complete automation of the laser processing by adding the visual quality control of the material before, during and after the process.

In addition to automatic focusing for inspection, Optotune’s EL-16-40 based module can reliably measure the object distance using the depth from focus (DFF) contrast algorithm. This allows to subsequently adjust the focal length on the right marking plane in less than a second. Being outside the laser beam path, the EL-16-40 lens can be integrated in this configuration regardless of the laser power class.

Systems with laser power levels up to 50 W can benefit from a configuration where the EL-10-42-OF lens is used for laser processing and the inline inspection at the same time. The inline camera in this case needs only simple camera optics. This approach not only greatly compacts the setup and reduces the cost, but also provides constant laser spots and constant image resolution in the entire, increased marking volume.

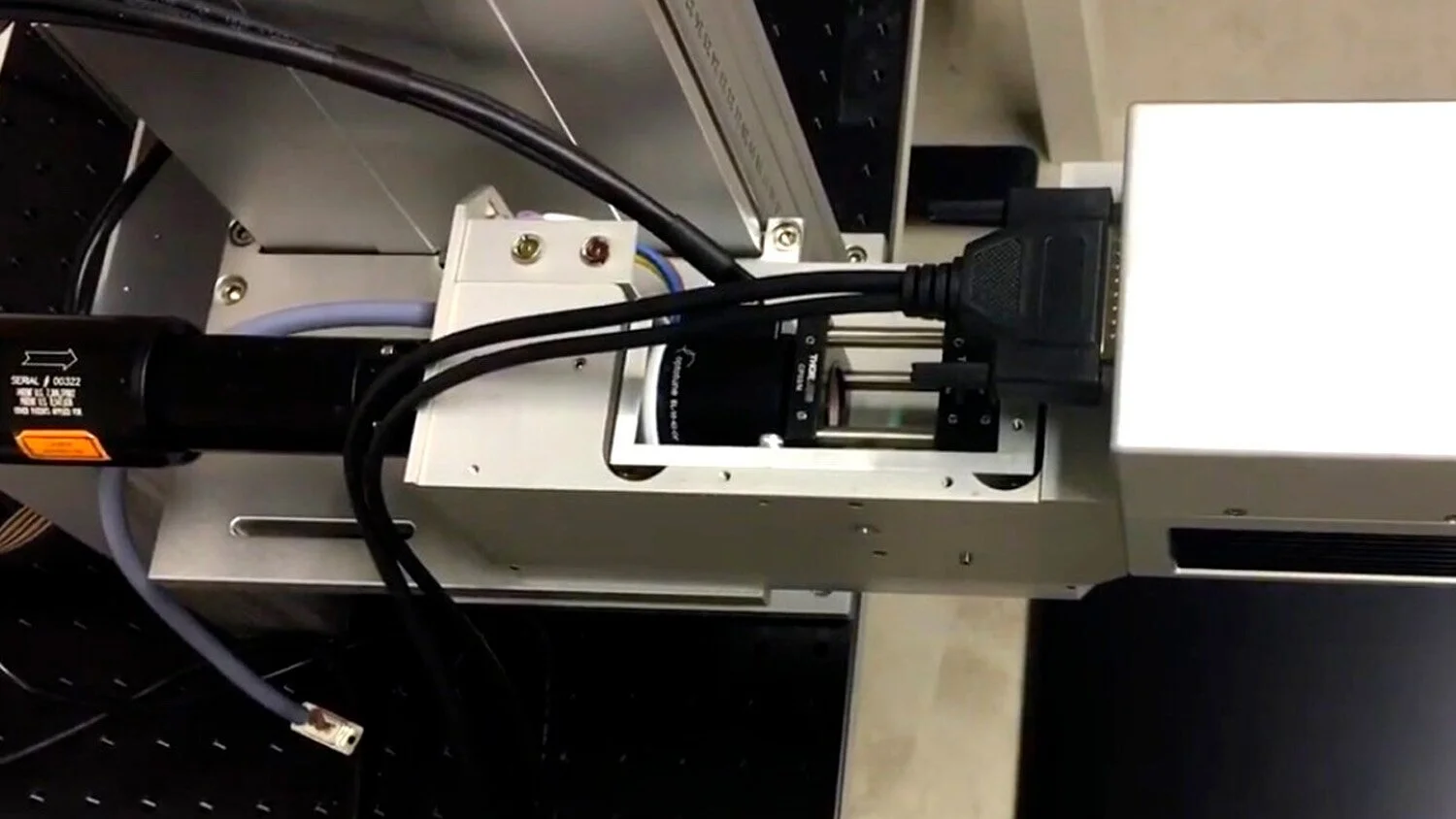

Inline inspection configuration with the EL-16-40 tunable lens

Inline inspection configuration with the EL-10-42 tunable lens

2D-mirrors for laser applications

Numerous compact and inexpensive systems can be easily realized with the Optotune’s 2D mirrors, in configurations with or without the tunable lenses. Applications vary from medical (ophthalmology) use cases, where low-power (up to 1 W) pulsed- or cw-lasers in the visible are usually used, to significantly more powerful laser beams in the NIR for applications such as surface cleaning.

With a mirror size of 15mm, the MR-15-30 2D mirror achieves up to +/- 50° optical deflection (100° FOV) in its standard non-resonant configuration (quasi-static on both axis). The mirror also includes a position feedback system, which allows it to be accurately PID-controlled, with different standard metal (gold or silver) and dielectric coatings.

Configuration with Optotune’s 2D mirror and (optional) tunable lens for laser applications

Contact Optotune if you require a customized product or wish to evaluate the EL-10-42-OF kit for your laser processing application.

Products: laser processing

EL-10-42-OF (End-of-life)

EL-E-OF-A

(End-of-life)

MR-15-30

MR-E-2